ABOUT US

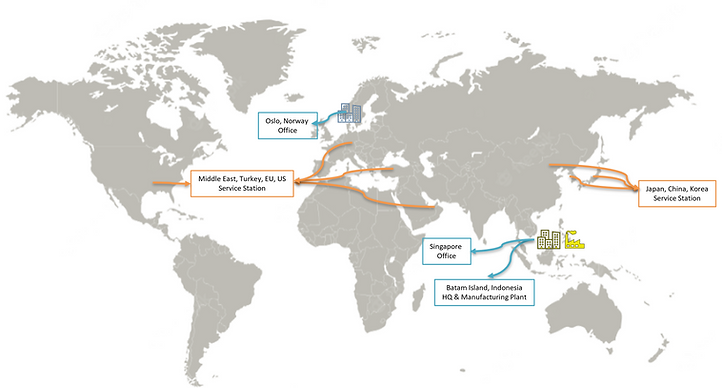

Feen Marine is a trusted manufacturer of Inert Gas Systems and Exhaust Gas Cleaning Systems, serving the global marine industries. We specialize in the in-house design and production of Inert Gas Systems, Nitrogen Generators, and EGCS, while also offering spare parts and after-sales service for vessels in operation. With over 20 years of experience in manufacturing, commissioning, and servicing gas treatment systems, our designs reflect a deep understanding of industry needs and operational challenges. We recognize the critical importance of system reliability, spare parts availability, and responsive after-sales support. Our customer relationships are built on open communication, enabling us to continuously improve our products through feedback and collaboration. Our manufacturing facility is strategically located on Batam Island, Indonesia, allowing us to serve key maritime markets efficiently. Our operations span Indonesia, Singapore, China, Japan, and Norway, ensuring regional presence and global reach. Originally established to design and manufacture Inert Gas and Nitrogen Generation Systems, we expanded into the Exhaust Gas Cleaning System market in 2018 to meet growing emission compliance demands. Since then, Feen Marine has successfully delivered over 600 systems to shipyards in Singapore, Korea, China, Poland, Indonesia, Turkey, the Philippines, and Japan. As of 2025, we have manufactured more than 60 Exhaust Gas Cleaning Systems for Feen Marine Scrubbers Inc., along with an additional 350 scrubber systems and 250 Inert Gas Systems under our parent company, Feen Marine Inc. Our installations include both new builds and retrofits, covering a wide range of vessel types including VLCCs, bulk carriers, chemical tankers, container ships, and container reefers.

KEY CAPABILITY

premium material

Crafted with top-tier European materials (SMO-254) to ensure durability and performance

all-stream integration

A single scrubber system manages exhaust from the main engine, auxiliary engines, and boilers

certified quality

Built to meet strict ISO standards for consistency and global compliance

craftmanship

Developed by a skilled Norwegian design team and supported by our in-house production experts.

At Feen Marine, our Exhaust Gas Cleaning Systems (EGCS) and Inert Gas Systems (IGS) are engineered to effectively reduce sulphur emissions from ships—delivering compliance, efficiency, and simplicity

simple operation

No moving parts or complex controls—designed for reliable, low-maintenance use

custom fit

Our EGCS and IGS units are tailored for both new builds and retrofits—adaptable to any vessel size

user centric design

Streamlined operation minimizes crew workload and reduces onboard complexity.

multi setting

EGCS Achieve sulphur removal targets of 0.5% or 0.1% with adjustable operational settings

REFERENCE

TRUSTED BY

contact us

OFFICE

Singapore

Storefriendly Bukit Merah

10 Jln Kilang Timor, #01-01

Singapore 159306

Indonesia

Menara Aria Office Tower

11th Floor

Harbourbay Batu Ampar

Batam, Indonesia

Tel: +627784888898

Norway

Fridtjof Nansens plass 4,

0160 Oslo

Norway

Manufacturing Plant - Indonesia

Sekupang Industrial Area,

Kampung Baru RT 003/ RW 003.

Kelurahan Tanjung Riau, Sekupang

Riau Island,

Batam, Indonesia

Sales (Spare-parts)

sales@feenmarine.com

Technical Assistance

Sales (Service attendance)

Warranty Assistance